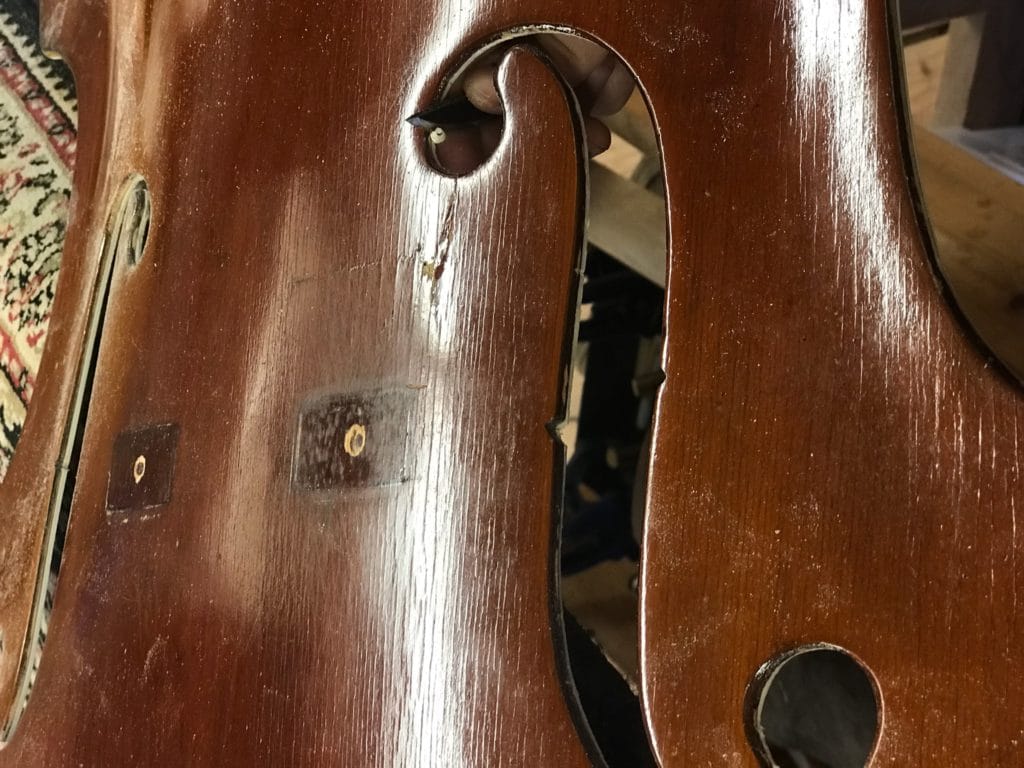

This American Standard double bass came in with a “loose” bass bar and arching deformations around the bridge/soundpost as well as the lower bout. Upon an internal inspection, the bass bar had not let go, the laminations had failed. We took off the top and were able to easily remove a layer of wood. Testing a few areas, we decided that just the one layer had failed and the others were holding. American Standards use fewer layers, but thicker layers, than other vintage laminates and even our own newly made laminated basses, so we re-laminated two thin layers into the top. The edges and ff holes were then recut and rounded over, and we began chalk fitting a new spruce bass bar. We also decided with the table deformations around the bridge/soundpost that a larger platform would be best to disperse the load over a greater area and to further help restore the arch. The arching was restored to new in both the lower section where the bass bar came off, as well as the bridge area. After some minor setup tweaks, this one is off to its owner to enjoy many more decades of play!

American Standard Delaminations…